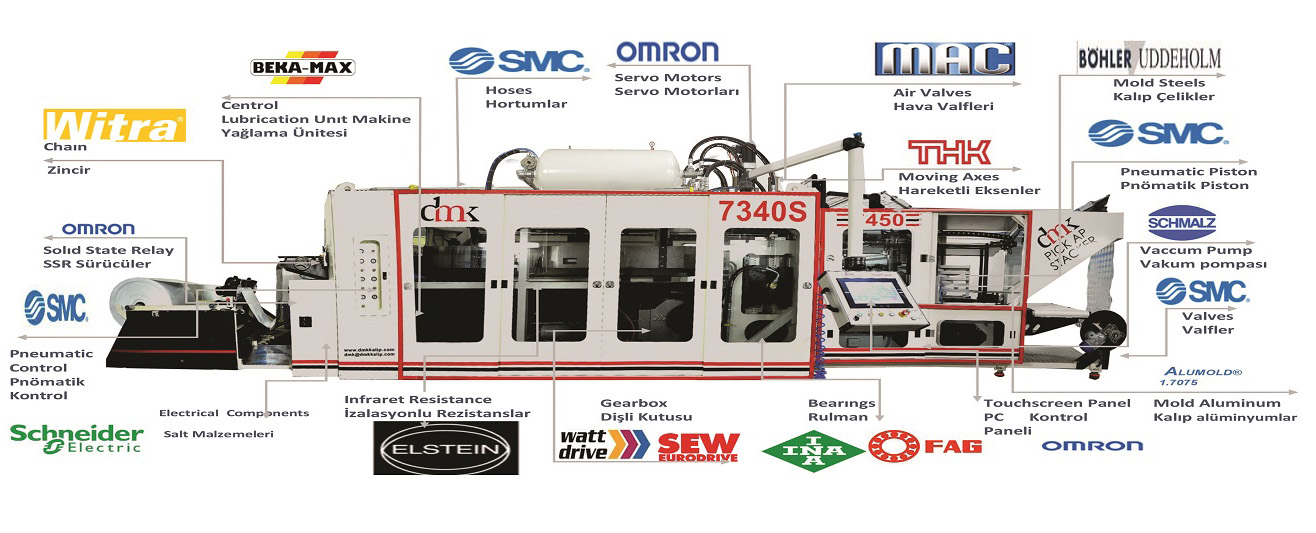

7340S THERMOFORMING MACHINE SPECIFICATION

- Speed: No Load Cycle : 0-40 Cycles/Min.

- Max. Forming Area: 730x400 mm

- Max. Sheet Width: 760 mm

- Min. Sheet Thickness: 0,30 mm

- Max. Sheet Thickness: 2 mm

- Pitch: 480mm

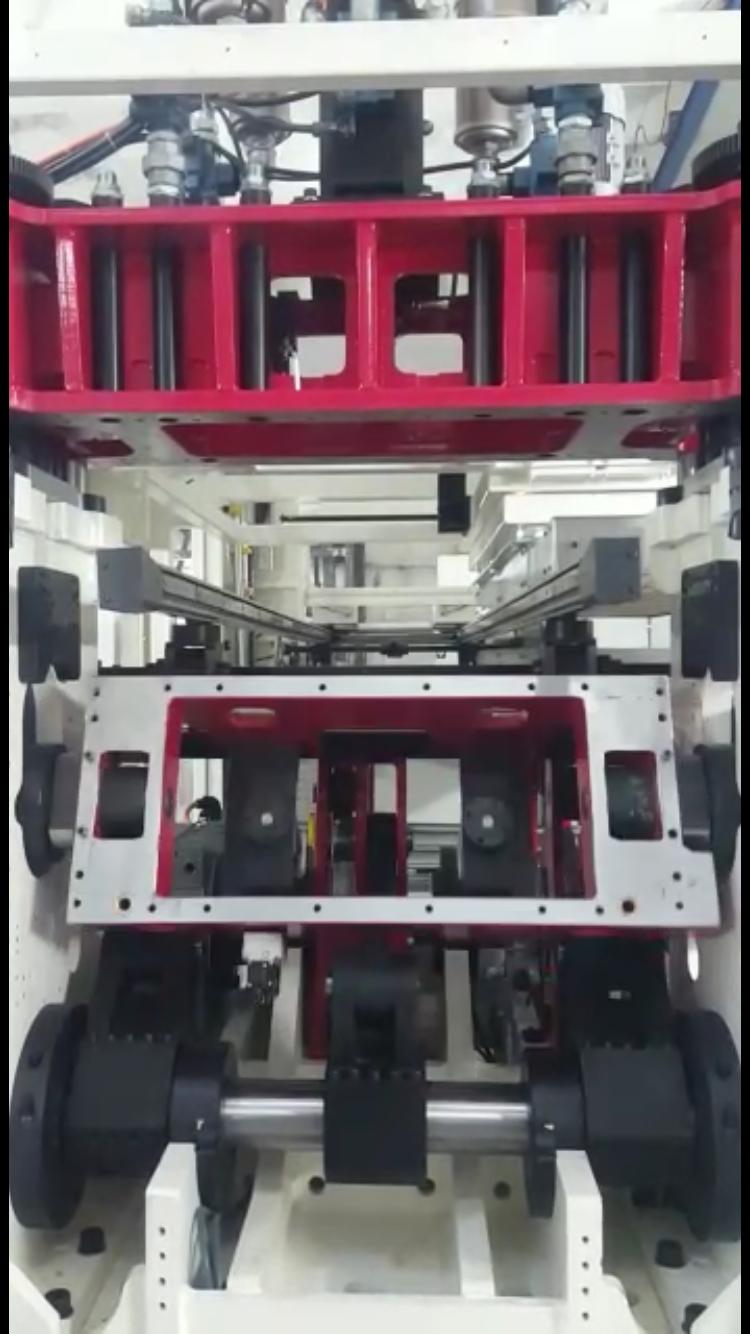

- Mould Pressing Power: 32.500 daN

- Forming Depth: 160 mm

- Air Consumption: 8 Bar 8 m² (Giriş filtreli sistem)

- Air System: 4-Point Trigger Valve Inlet-Special Large Tanks

- Power Consumption: 222 kW (Max-Load)

- Water Pressure & Temperature: 3,4 bar, 10°c 50.000 Cal (Outomatic Control System)

- Water Inlet-Outlet: Lower Mould –Upper Mould-Repellent-Chain levers 4 Inputs 4 Outputs

- Pneumatic Equipment: Smc,Mac

- Weight: 14.750 kg

- Formable Raw Material: PP-PS-PSV-PET-ABS-PLA

- Mould Cutting Adjustment System: Motor Special production Gearbox Gear Shaft .System

- Communication: Ethercat Motion Control

- Automatic Machine Grease: Bekamaks

- Automatic Chain Oil: Bekamaks

- Chain Levers: Aluminum full size water cooled 2379 58-60-hrc steel protected special system.. Heat Protection , Reflector. Spring automatic tensioning system

- Mould Change: Special Tools. Manuel Crane With Chain

- Coil Feeding: Hydraulic system 1800-1500 kg capacity

- Seal System: Special Design Mechanic - 50x50 THK Ball Screw.

- Moving Cable and Hose Transfer Channel: CKS Moving Cable

- Loading Program to Memory: Automatic Recipe Saving

- Remote Control and monitoring: with Internet Connection

- Vacuum Pomp: 2,2 kw Schmalz

- Work Safety: Closed cabinet rail cover and switch system

- Main Servo Motor: 7,5 kW Omron Panel

- Seal Servo Motor: 7,5 kW Omron Break

- Chain Servo Motor: 5 kW Omron without Break

- Gear Box: Motive-Watt Drive - Sew-Eurodrive

- Electrical & Electronic Equipment: Omron

- Operator Panel: 15’’ Omron

- Resistance: Ferran Reflector, Eintegin FSR(Germany) 650-1000 V

- Number of Resistances: Total : 228 Upper:11 x 10 & 7 x 6 Lower 11 x 12 Sheet Foil Inlet Chain Resistance 2 x 2 pcs

- Colour: RAL 9010 ve RAL 9017 RAL 3002 RAL 7011

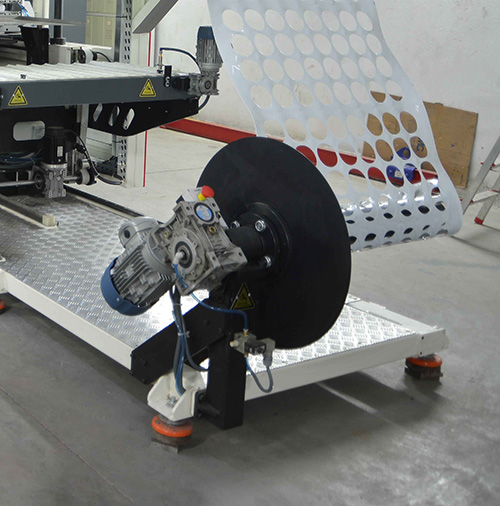

Unwinder

- Roll Lifting System - Hydraulic

- Able to Work with Double Roll

- Analog controlled, non- Stop Roll Opener

- Max. roll diameter: 1900 mm

- Formable Raw Material: PP-PS-PSV-PET-ABS-PLA

Chain

- High precision chain motion system with servo motorZincir servo motor: 5 kW Omron without Brake

- Chain Levers: Aluminum full size water cooled 2379 58-60-hrc steel protected special system.

- Heat protection Ferran reflective reflector. Spring automatic tensioning system.

- Chain Lubrication system (BEKA-MAX) PC controlled

- Max. Sheet Width: 760 mm

- Min. Sheet Thickness: 0,30 mm

- Max. Sheet Thickness : 2 mm

Heaters

- Sagging sensor Control

- Resistance: Ferran Reflector, Eintegin FSR(Germany) 650-1000 V

- Number of the Resistance: Total : 228 Upper:11 x 10 & 7 x 6 Lower 11 x 12 Sheet Foil Inlet Chain Resistance 2 x 2 pcs

Vacuum Robot Stacker

- Pneumatic Equipment: Smc

- Carier Servo Motor: 5 kw Omron with Brake

- Elevator Servo Motor: 1,5 kw Omron with Brake

- Servo Vertical Motor: 2 kw Omron with Brake

- Servo Horizontal Motor: 2 kw Omron with brake

- Front Puller Asynchronous Motor: 1,1 kw Frenli Motive

- Output Winder Asynchronous Motor: 1,5 kw Motive

- Vacuum Pump: 2,2 kw Schmalz

- Conveyor Asynchronous Motor Power: 0,18 kw

- Removing from stacker mould: 0,25 kw, Lineer Trolley Rack and Motorized System

- Electrical & Electronic Equipment: Omron, Sick

- Min. Stacking Quantity: 25 Pcs

- Max. Stacking Quantity: 100 Pcs

- Min. Product Depth: 25 mm

- Max. Product Depth: 180mm

- Stacker Changing: Manual Push and Pull Slides

- Waste Wrapping: Wrapping to Opposite Side(pneumatic piston discharging)

- In-line Waste Crushing Direction: machine opposite and cabin direction system

- Work Safety: Closed cabinet rail cover and switch system

- Rotation Axis Mechanical Cam: 180°

- Transporting the Product to the Conveyor: Central and sweep piston with linear trolley

- Elevator Collector: Linear Trolley Rack System With Belt Up and Down

- Product Packaging Transfer: Belt Conveyor

- • Product Removal: Vacuum Precision Mandrel System

- Haberleşme: Ethercat Motion Kontrol

- Loading Program to Memory: Automatic Recipe Saving

- Stacked Product Transfer: Vertical and Horizontal Linear Trolley Piston

- Stacker Brush Transfer From the Mould: Belt Pulley Linear Trolley

- Moving cable and hose transfer: CKS dynamic cable Channel

- Auto Grease Lubrication: Bekamaks

- Defective Product Separation: Separation with Hopper Outlet

Scrap Winder

- Asynchronous Winder Motor with Electronic Torque Control

- Pneumatic discharging system of scrap

Electrical Panel

- Electrical panel, installation in accordance with CE safety norms

- High Quality Electrical and Electronic Components

- In-panel air conditioner cooled - 1000 watts

- BECKER, SEW, SIEMENS, MOELLER, OMRON, SCHNEIDER

- Power Consumption: 222 kW (Max-Load)